HOMA for Rolling train

The main application for switches is the switch on and off of the engine output (AC or DC) in case of errors, maintenance work or mounting. It moderates or brakes motors until the point of stand still.

Rolling train. Products

HOMA Switchgear

For over 60 years

HOMA switches are being built into different applications for more than 60 years and have been supplied to more than 100 countries. Due to the worldwide experience of HOMA, many national and international norms can be fullfield and have conducted a vast number of type tests for our products. We equip our switches with coils that can be operated worldwide with 60V to 480V AC/DC. The worldwide distribution network ensures minimal downtimes in case of a break down. HOMA is known for short delivery times and due to its modular design, switches can be assembled and delivered within 24 hours.

Switching

Air-break contactors and combinations of switches to deal with normal to complicated switching activities for all types of electrical loads.

Isolation

Sliding contacts, air-break contactors and air- or water-cooled high current switches for galvanic interruption of circuits without a control current for technical or safety reasons.

Distributing

Different types of commutators to select different sources or for an alternative supply of the electrical load circuit.

Controlling

Commutators and pole-reversal contactor including associated control systems, reversing contactors etc. for process-related reversion of the electrical current or rotational direction; braking contactors for switchoff for drives that simultaneously trigger dynamic braking systems.

Regulating

Starting contactor / rotor-short circuit contactor, as well as starting coupling contactor / cascade coupling contactor for large machinery in association with subsynchronous static converter systems cascade; capacitor contactors for balancing or compensating inductive electrical loads. Starting, damping and discharge resistors.

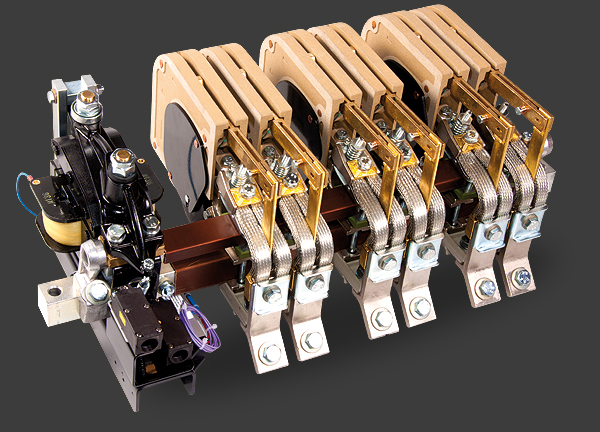

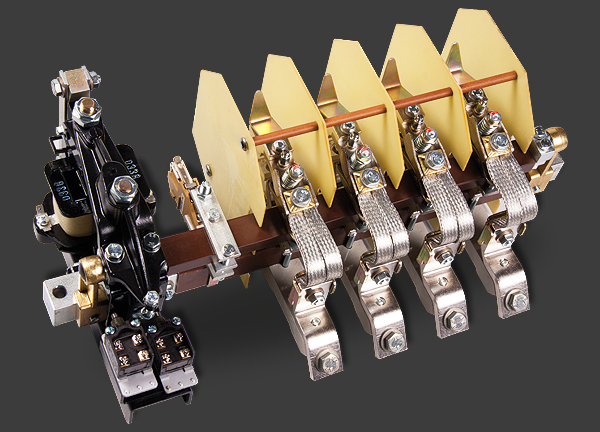

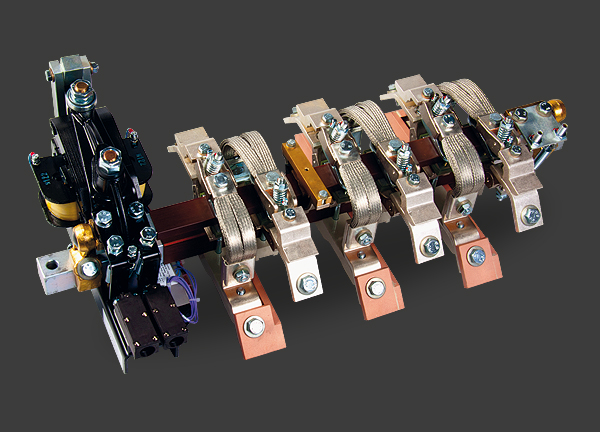

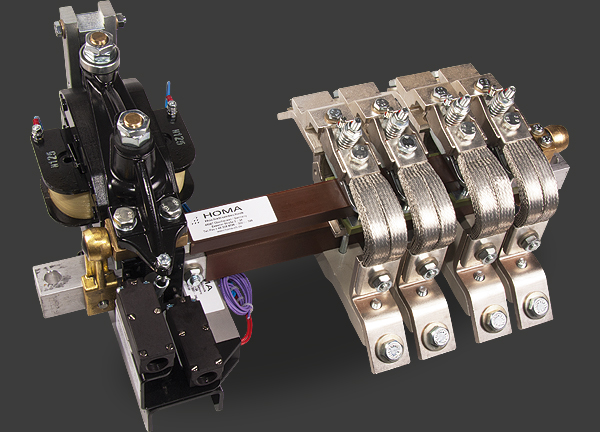

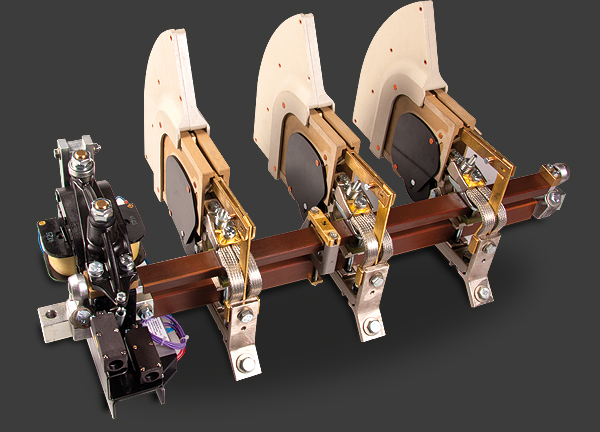

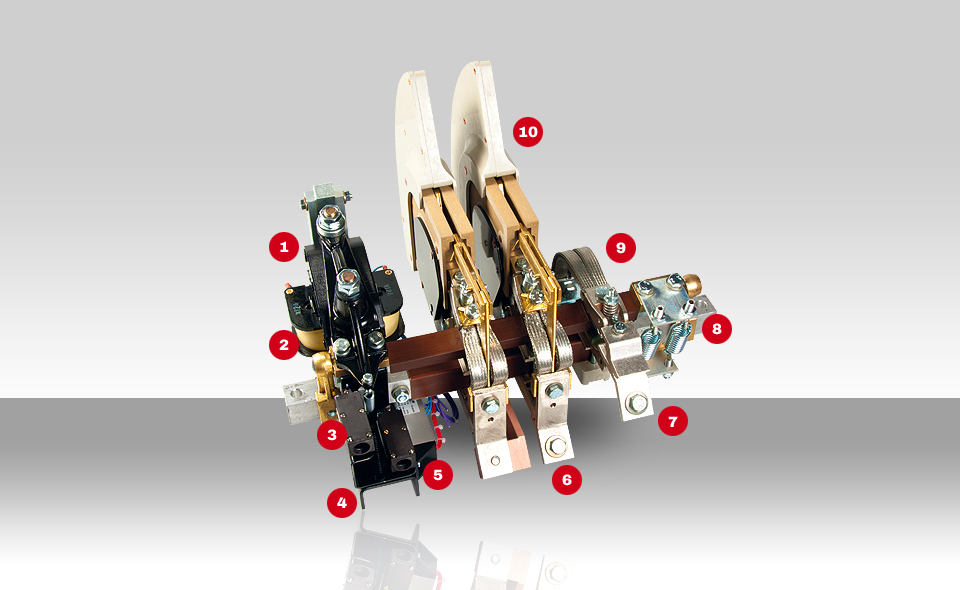

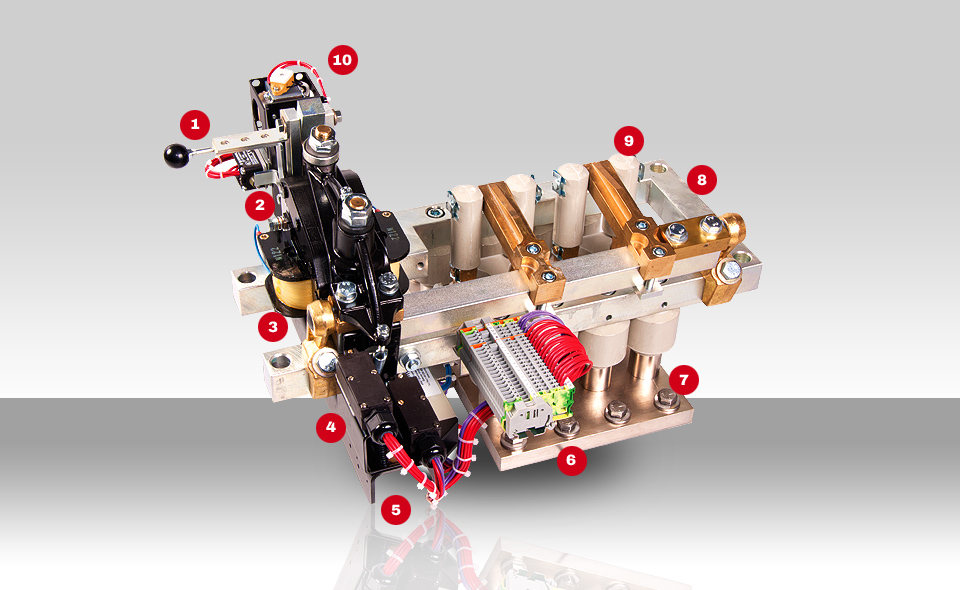

HOMA Bar mounted Contactors

In HOMA Bar mounted Contactors current-carrying components are organized on the basis of a main frame construction. All required modules are arranged on top of a single frame (bar), for example: Magnet system, Terminal plate for power circuit, Switch locking system and Movable contacts. The two examples below (G500 / HAT-2W) illustrate the construction.

TYP G500

TYP HAT-2W

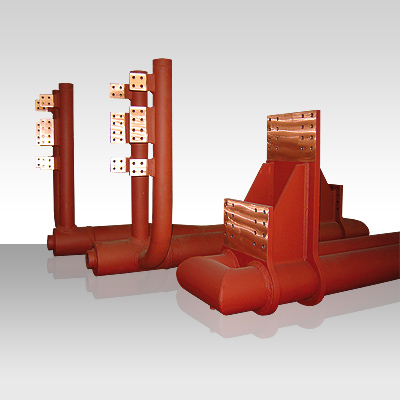

HOMA Cables

As a system supplier in the field of high current technology our product portfolio includes a variety of power connections. Beside a high flexibility, our products are known for a long life time and reliability.

Current Carrying Connections

Further products:

- High current cables 95mm² up to 8.000mm² air- and water cooled

- Flexible connections/braids (Copper and Aluminium)

- Press welded shunts (Copper)

- Bus bars

- Copper tubes or bus systems

- Insulating materials

- Starting - damping - discharge resistors

- Insulator - supports up to 3000 V

- Bus bar - supports

- Vertically adjustable insulators

- High current lines (transformer house)

- Contact jaws

- Electrode arm systems