HOMA Bar mounted contactors: DC contactors

AC and DC bar contactors have been an integral part of the HOMA High Current Technology range for more than 60 years. HOMA develops and manufactures bar gates for railway technology, foundries and steelworks, solar and wind turbines, starters, battery test equipment, ripple control systems, rolling and crane systems.

HOMA is a system supplier to well-known manufacturers. In addition to the production of switchgear, HOMA is also able to solve complex tasks for customers and to develop, manufacture and install complete control cabinets including power electronics.

The DC bar contactor is part of the extensive range of switching devices. Also in the range: Special accessories to expand the function of large contactors in the context of overcurrent shutdown.

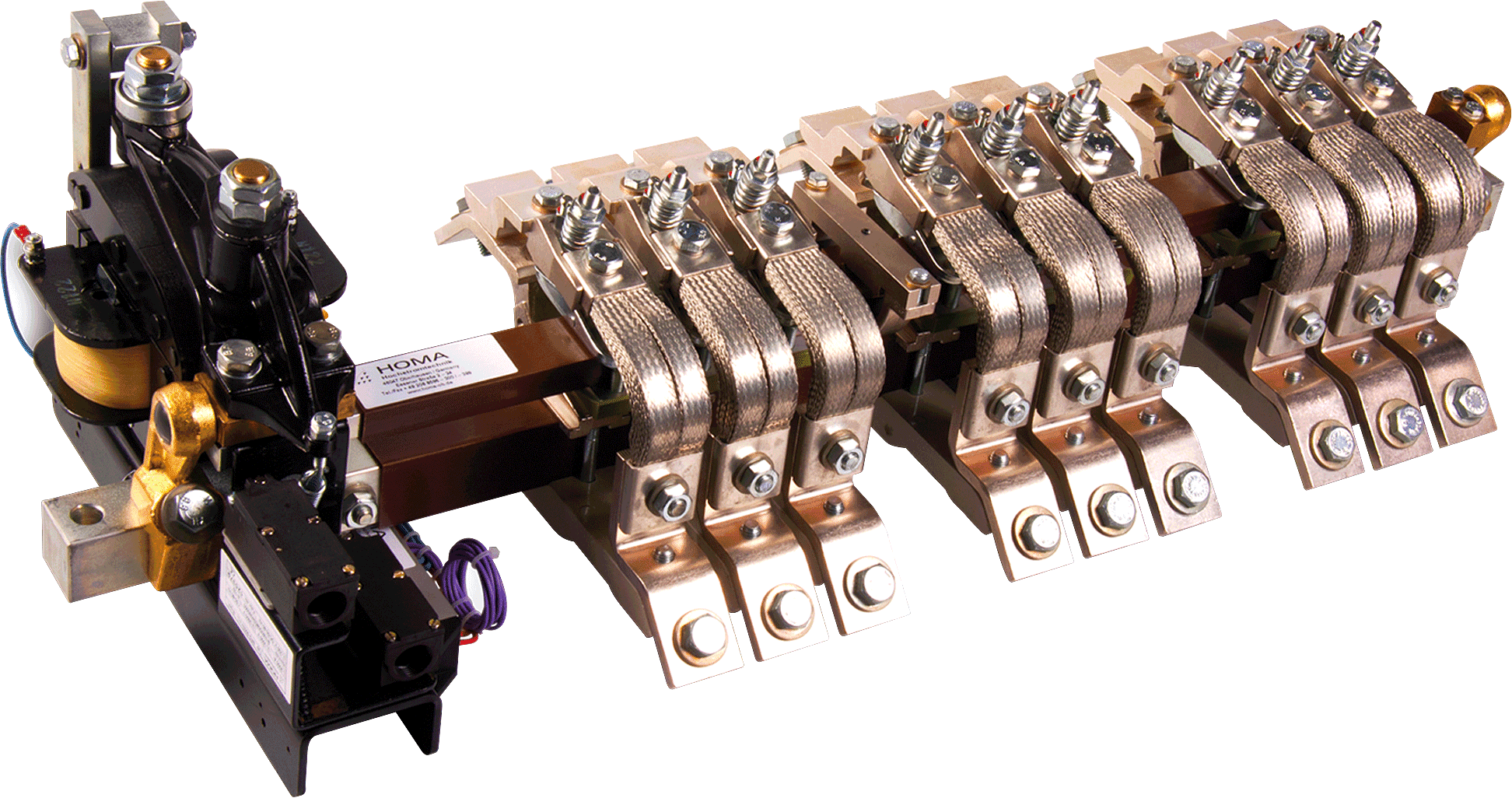

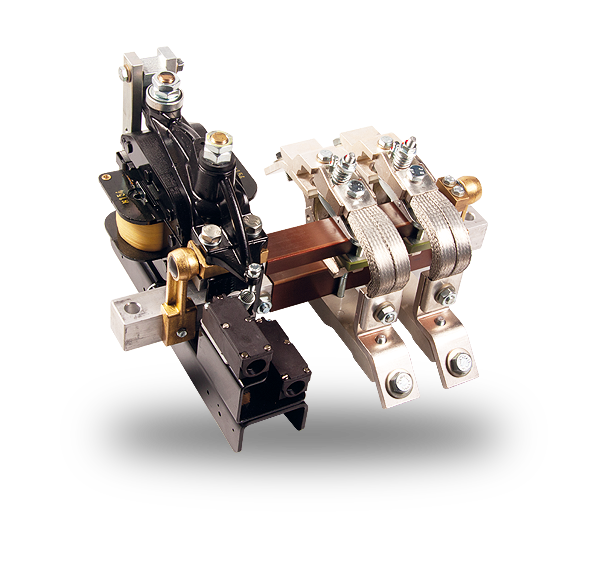

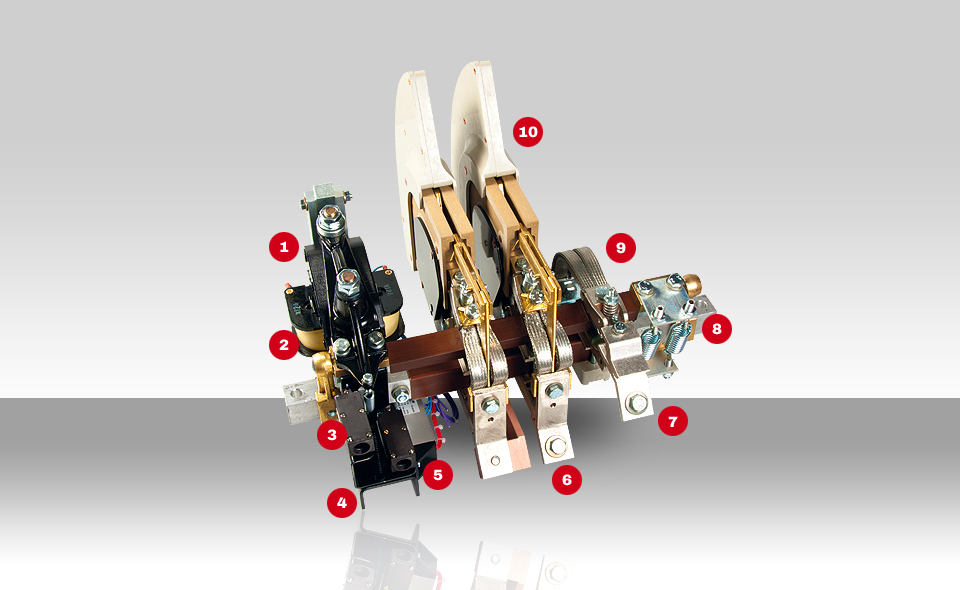

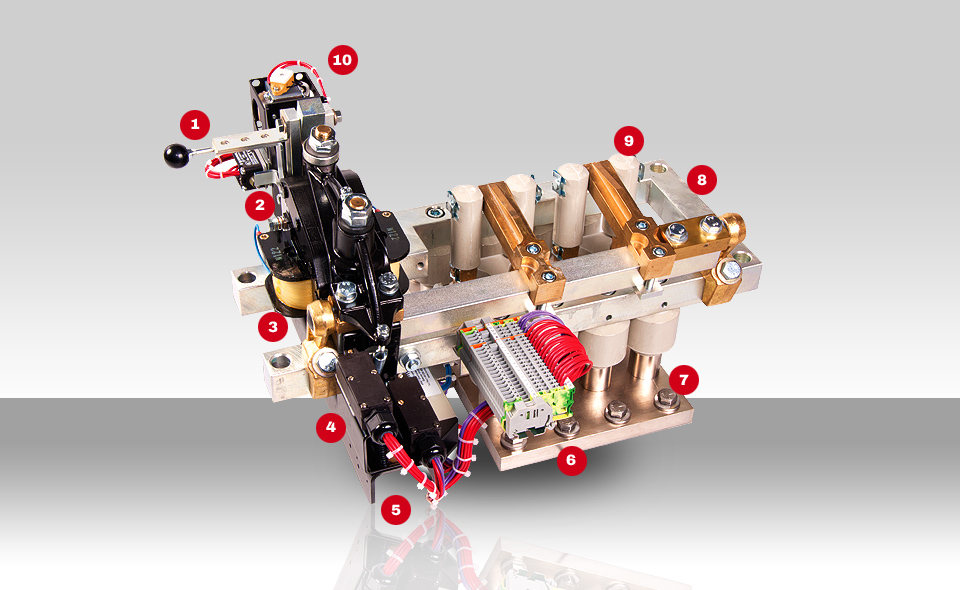

HOMA Bar mounted Contactors

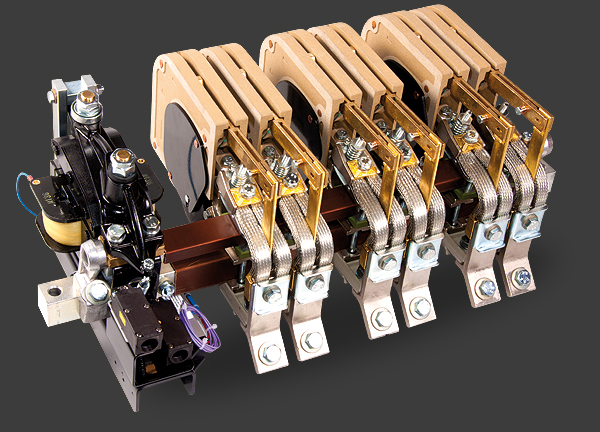

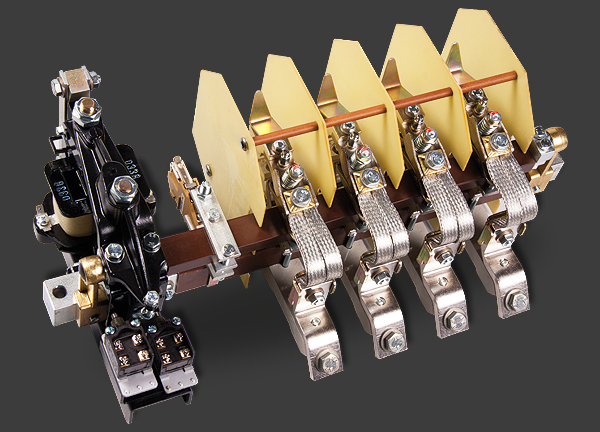

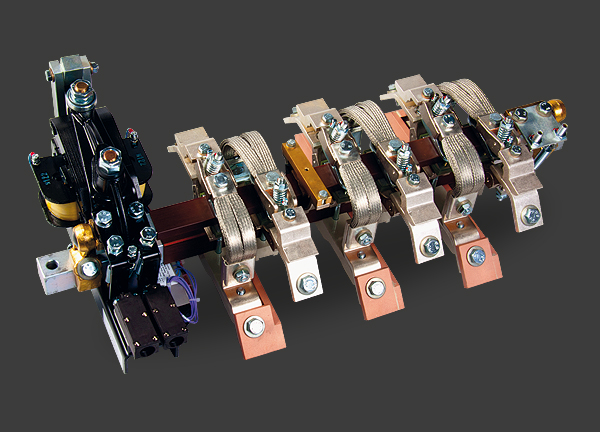

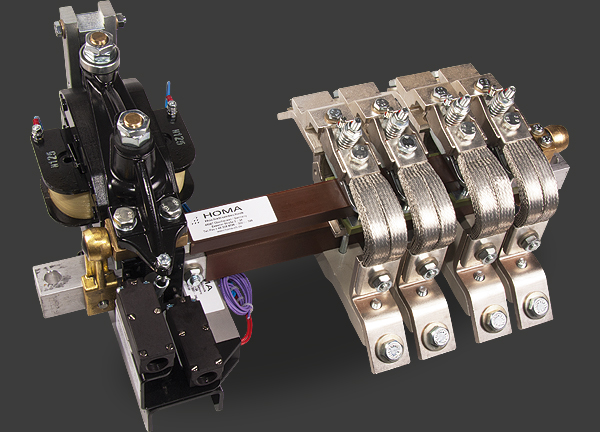

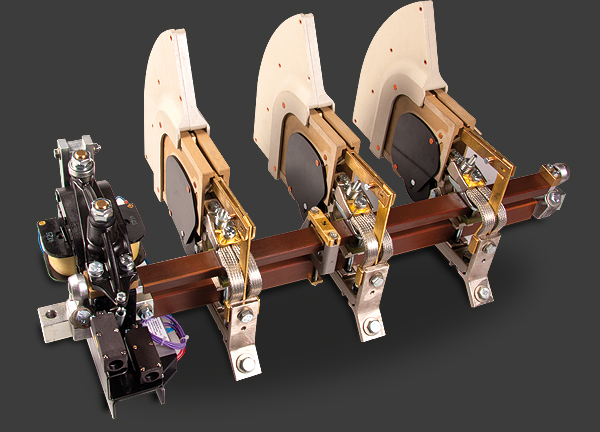

In HOMA Bar mounted Contactors current-carrying components are organized on the basis of a main frame construction. All required modules are arranged on top of a single frame (bar), for example: Magnet system, Terminal plate for power circuit, Switch locking system and Movable contacts. The two examples below (G500 / HAT-2W) illustrate the construction.

TYP G500

TYP HAT-2W

HOMA DC Switchgear

For over 60 years

For more than 60 years HOMA switches are being built into different applications and have been supplied to more than 100 countries. Due to the worldwide experience of HOMA, many national and international norms can be fullfield and have conducted a vast number of type tests for our products. We equip our switches with coils that can be operated worldwide with 60V to 480V AC/DC. The worldwide distribution network ensures minimal downtimes in case of a break down. HOMA is known for short delivery times and due to its modular design, switches can be assembled and delivered within 24 hours.

Switching

Air-break contactors and combinations of switches to deal with normal to complicated switching activities for all types of electrical loads.

Isolation

Sliding contacts, air-break contactors and air- or water-cooled high current switches for galvanic interruption of circuits without a control current for technical or safety reasons.

Distributing

Different types of commutators to select different sources or for an alternative supply of the electrical load circuit.

Controlling

Commutators and pole-reversal contactor including associated control systems, reversing contactors etc. for process-related reversion of the electrical current or rotational direction; braking contactors for switchoff for drives that simultaneously trigger dynamic braking systems.

Regulating

Starting contactor / rotor-short circuit contactor, as well as starting coupling contactor / cascade coupling contactor for large machinery in association with subsynchronous static converter systems cascade; capacitor contactors for balancing or compensating inductive electrical loads. Starting, damping and discharge resistors.

Products

G800-Rail Negative Earthing and Shorting Switch

G1400-Rail Negative Earthing and Shorting Switch

G800 On Load Contactor

NFG 500V O.L. Negative Earthing Switch

KMT Disconnector

HOMA Over-current sensor

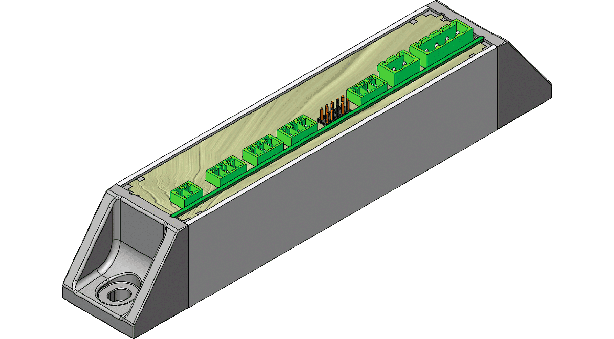

For expanding the function of large Contactors for over-current Deactivation

The device enables the monitoring of up to three phase currents. If one of the thresholds set via the jumper is exceeded, the coil current (field current) of the large contactor is interrupted and, thus, deactivated, in the event of over-current. Only one common threshold can be set for the three sensors. Both AC and DC currents can be monitored. In the case of DC currents, the triggering does not depend on the current direction. The system can also be utilised to monitor alternating current systems. The three sensors can then be assigned to each phase.

The sensors themselves must be connected directly to the busbars. They can be connected via screws or cable ties (black). The current measuring functions by measuring the field strength H that surrounds every live conductor. Due to the fact that the field strength depends on the distance of the measuring point from the conductor, the sensors must be installed in accordance with the instructions.

The sensors are delivered with a 1 m long connection cable as standard and connected to the control unit belonging to the system. Neither connection work nor adjustments need to be carried out on the sensors.