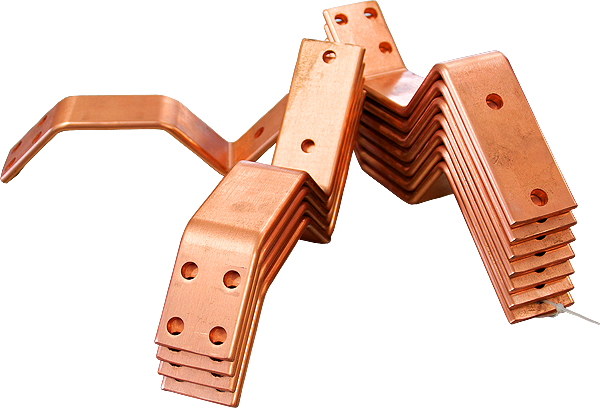

HOMA Busbar

For years, HOMA has stood for individual and high-quality products in the sector of copper bars, flexible current strips, current tubes and much more. With our modern machinery, we can offer a broad manufacturing portfolio that meets your requirements with the highest precision. In all variants. You should see for yourself.

Precision in Copper

Automated manufacturing

HOMA has an automated copper rail production with CNC punching and bending machines. The following dimensions can be produced in this way::

- Material thickness (t) = 10 - 50 mm

- Bending radius inside R5

- Bends up to = max. 10 mm

Mechanical production

HOMA uses a Caretta water jet and plasma cutting machine especially for customers in the field of furnace construction. This machine allows HOMA to process plates with dimensions of up to 9m x 3.5m. In addition to cutting the conductor rails to size, HOMA also offers mechanical processing, bending, welding and cooling channels from a single source. The following dimensions can be produced in this way:

- Material thickness (t) = 50 - 10 mm

- Material width (b) = 20 - 200 mm

- Bending radius inside R5

- Bends up to t = max. 10 mm

Busbar options

Individual

HOMA offers you the following options for optimizing your busbars:

- Thread

- Milling chamfers

- Individual labelling of the rails

- Raychem® shrink tubing according to drawing

- Press-in of rivets